Background

A new version of UL 1642 was released. An alternative to heavy impact tests is added for pouch cells. The specific requirements are: For pouch cell with capacity that are greater than 300 mAh, if pass the heavy impact test were not passed, they can be subjected to Section 14A round rod extrusion test.

Pouch cell has no hard case, which often leads to cell rupture, tap fracture, debris flying out and other serious damage caused by failure in heavy impact test, and makes it impossible to detect the internal short circuit caused by the design defect or process defect. With round rod crush test, possible defects in the cell can be detected without damaging the cell structure. The revision was made with this situation in consideration.

Testing flow

- The sample is fully charged as recommended by the manufacturer

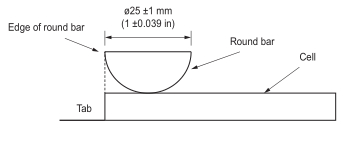

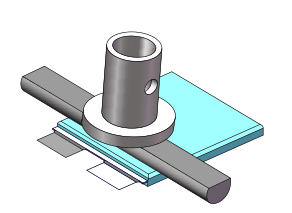

- Place a sample on a flat surface. Put a round steel rod with a diameter of 25±1mm on the top of the sample. The edge of the rod should be aligned with the top edge of the cell, with the vertical axis perpendicular to the tab (FIG. 1). The length of the rod should be at least 5mm wider than each edge of the testing sample. For cells with positive and negative tabs on opposite sides, each side of the tab needs to be tested. Each side of tab should be tested on different samples.

- Measurement of thickness (tolerance ±0.1mm) for cells shall be performed prior to testing in accordance with Appendix A of IEC 61960-3 (Secondary cells and batteries containing alkaline or other non-acidic electrolytes – Portable secondary lithium cells and batteries – Part 3: Prismatic and cylindrical lithium secondary cells and batteries)

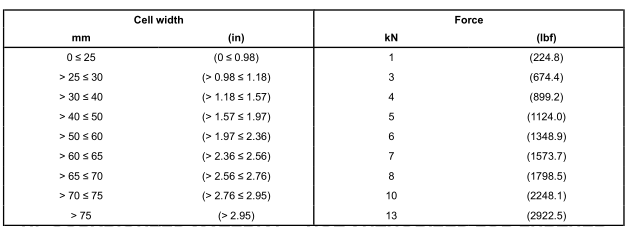

- Then squeeze pressure is applied on the round rod and the displacement in the vertical direction is recorded (FIG. 2). The moving speed of the pressing plate shall not be greater than 0.1mm /s. When the deformation of the cell reaches 13±1% of the thickness of the cell, or the pressure reaches the force shown in Table 1 (different cell thicknesses correspond to different force values), stop the plate displacement and hold it for 30s. The test ends.

- No fire or explosion of samples.

Experimental analysis

- Selection of extrusion position: the pole tab area is generally the weak area of the pouch cell, and the tab position bears the greatest stress when being squeezed. The reasons are:

a) Uneven thickness distribution (uneven thickness between the pole tab and the surrounding active substance leads to uneven stress distribution)

b) Welding marks in the tab area (stress distribution at the weld point and non-weld point)

- Selection of round rod: The diameter of the round rod is 25mm. This value is selected to cover the entire area of the pole tab in the cell (especially the area covering the pole tab solder joint).

- 13±1% deformation: At present, the thinnest cell thickness on the market is 2mm. Due to the influence of battery enclosure or packaging process, at least 8% type variable is required for compression to the pole tab solder joint, but it will directly lead to electrode cracking if type variable is too large. A value of 13±1% was selected in this revision, referring to the medium variable 15% in the extrusion test in IEC 62660-3.

- Sample selection: It should be noted that this test is only for pouch cells whose capacity is greater than 300mAh and that have not been hit by heavy objects. 5 samples are required. Cylindrical or prismatic cells and pouch cells hit by heavy objects aren’t necessary to be considered for this test.

Summary

The new round rod extrusion test is different from the original extrusion test of UL 1642. The original extrusion test is to use flat extrusion, and apply a constant 13kN force without holding time. It’s applicable to all types of cell. This test examines the mechanical strength of the cell as a whole (including the case) and its ability to withstand mechanical stress; while the round rod extrusion only test a part of cell, the smaller area of the indenter will make the internal stress concentrated, easy to lead to internal short circuit. Especially, the extrusion position is selected in the weak area of the pole tab welding, which can better investigate the safety performance of the cell.

At present, this round rod method is also used in the extrusion test of pouch cell in GB 31241. MCM has rich testing experience in this operation.

Post time: Nov-16-2022