Background

The thermal propagation of a module experiences following stages: Heat accumulation after cell thermal abuse, cell thermal runaway and then module thermal runaway. Thermal runaway from a single cell is not influential; however, when the heat spread to other cells, the propagation will cause a domino effect, leading to the thermal runaway of the whole module, releasing massive energy. Figure 1 shows the result of thermal runaway test. The module is on fire due to irresistible propagation.

The heat conductivity inner a cell will be different according to different directions. The coefficient of heat conductivity will be higher in the direction parallel with the roll core of a cell; while the direction that is vertical to the roll core has lower conductivity. Therefore thermal spread from side to side between cells is faster than it does through tabs to cells. Therefore the propagation can be seen as a one-dimension propagation. As battery modules are designed for higher energy density, the space between cells is getting smaller, which will worsen thermal propagation. Therefore, suppressing or blocking the spread of heat in the module will be considered as an effective way to decrease hazards.

The way to suppress thermal runaway in a module

We can restrain thermal runaway actively or passively.

Active suppress

Active thermal spread suppression is mostly based on thermal management system, like:

1) Set cooling pipes on the bottom or the inner sides of a module, and fill with cooling liquid. The flowing of cooling liquid can effectively decrease the propagation.

2) Set up fire extinction pipes on the top a module. When there’s thermal runaway, the high temperature gas released from battery will trigger the pipes to spray out extinguishant to suppress propagation.

However, a thermal management requires extra components, lead to higher cost and lower energy density. There’s also possibility that the management system may not take effect.

Passive suppression

Passive suppression works by blocking propagation through adiabatic material between thermal runaway cells and normal cells.

Normally the material should feature in:

- Low thermal conductivity. This is to lower the speed of heat spreading.

- High temperature resistance. The material should not resolve under high temperature and lose the ability of thermal resistance.

- Low density. This is to lower the influence of volume-energy rate and mass-energy rate.

The ideal material can meanwhile block the heat spreading as well as absorb the heat.

Analysis on material

- Aerogel

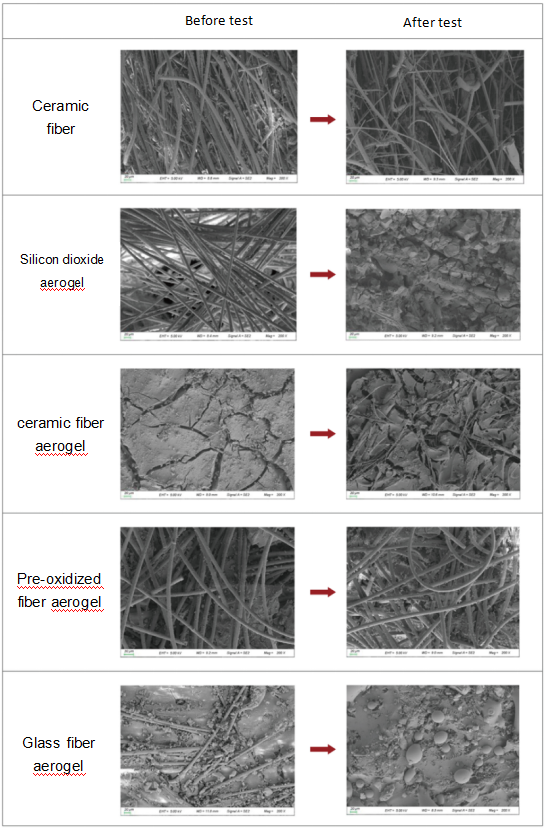

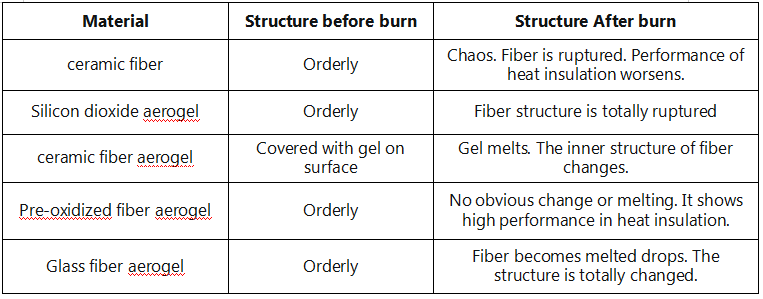

Aerogel is named as “the lightest heat insulation material”. It is well performed in heat insulation and weigh light. It is widely used in battery module for thermal propagation protection. There are many kinds of aerogel, like silicon dioxide aerogel, aerogel, glass fiber aerogel and pre-oxidized fiber. Aerogel heat insulation layer of different materials have various impact on thermal runaway. This is because the variety of thermal conductivity coefficient, which is highly related to its micro structure. Figure 2 shows SEM appearance of different material before and after burn.

Research shows that though fiber heat insulation is lower in price, the performance of blocking heat propagation is worse than aerogel material. Among different kinds of aerogel materials, pre-oxidized fiber aerogel perform the best, as it maintains the structure after burn. Ceramic fiber aerogel also performs well in heat insulation.

- Phase change material

Phase change material is also widely used for suppressing thermal runaway propagation due to its storing heat. Wax is a common PCM, with stable phase change temperature. During thermal runaway, heat is massively released. Therefore PCM should have high performance of absorbing heat. However, wax has low heat conductivity, which will influence heat absorbing. To promote its performance, researchers try to combine wax with other materials, like adding metal particle, use metal foam to load PCM, add graphite, carbon nano tube or expanded graphite, etc. Expanded graphite can also restrain the flame caused by thermal runaway.

Hydrophilic polymer is also a kind of PCM for restraining thermal runway. Common hydrophilic polymer materials are: colloidal silicon dioxide, saturated calcium chloride solution, Tetraethyl phosphate, tetraphenyl hydrogen phosphate, sodium polyacrylate, etc.

- Hybrid material

Thermal runaway cannot be restrained if we only rely on aerogel. To successfully insulate the heat, we need to combine the aerogel with PCM.

Besides the hybrid material, we can also construct multi-layer material with various thermal conductivity coefficients in different directions. We can use high thermal conductivity material to conduct the heat out of module, and put heat insulation material between cells to restrict thermal propagation.

Conclusion

To control thermal runaway propagation is a complicated subject. Some manufacturers made some solutions to suppress the heat spreading, but they are still searching for something new, in order to lower the cost and the influence on energy density. We are still focusing on the latest research. There is no “super material” that can totally block thermal runaway. It requires many experiments to get the best solutions.

Post time: Mar-10-2023